Global Reach, Local Expertise

Sustainable Cocopeat Solutions,

Powered by State of the Art Infrastructure

Husk Sourcing

We source coconut husks within a 50 km radius, promoting local livelihoods while minimizing transportation emissions. This approach supports regional economies, reduces environmental impact, and aligns with our commitment to sustainability. By choosing local materials, we ensure quality, foster community growth, and contribute to a healthier planet.

Pith

The coconut husk undergoes hammering to separate the fiber and pith. The pith is then carefully screened to eliminate excess fiber and sand, ensuring a clean, refined product. This process enhances the quality and usability of the pith, making it suitable for various applications like gardening and industrial use.

Crunch

The coconut husk is shredded into fine particles using a specialized crunching machine, cutting the fiber into 10mm lengths. This process retains the husk's natural ratio of fiber and pith, creating a balanced material ideal for growing plants.

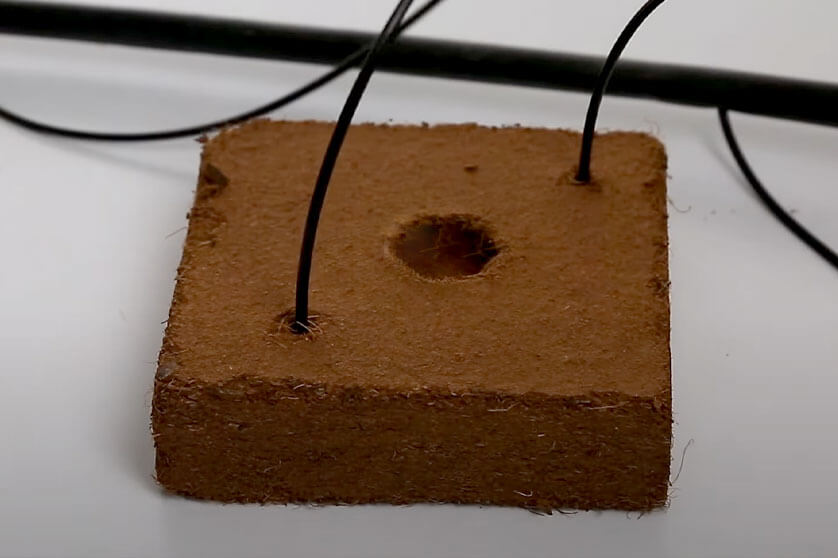

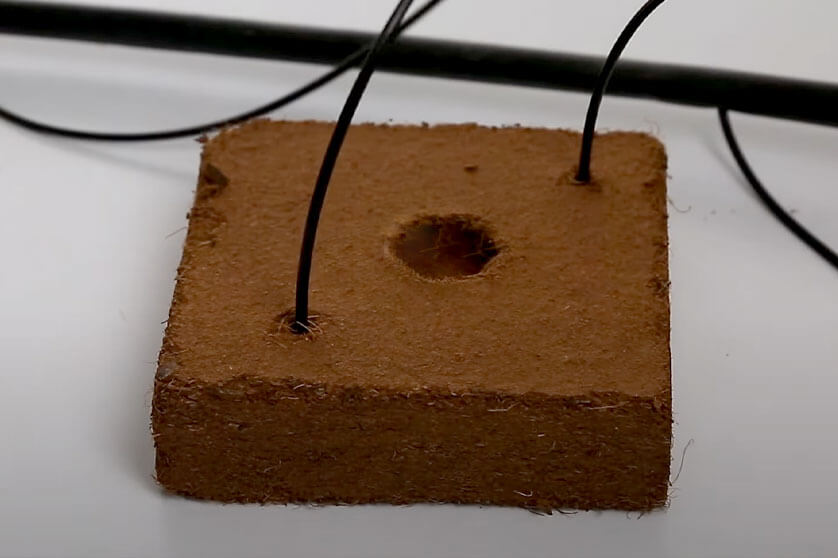

Pips & Chips

Coconut husks are cut into various thicknesses and processed into cube-like chips. These chips, available in different sizes, offer diverse water-holding capacities and air porosity, optimizing root zone conditions. This adaptability makes them ideal for horticultural applications, supporting healthy plant growth with enhanced moisture retention and aeration.

Washing

Our washing tanks reduce the natural salt content in coir material, ensuring its suitability for various applications. The coir undergoes extensive washing using a specialized sprinkling system to remove excess elements. This thorough process ensures high-quality output, tailored to meet specific customer requirements for horticulture and industrial use.

Waste water Treatment

The wastewater generated from washing coir material is treated to meet pollution board standards. Our in-house developed treatment process ensures effective purification, minimizing environmental impact. This sustainable approach reflects our commitment to eco-friendly practices, safeguarding natural resources while maintaining compliance with regulatory requirements.

Drying

The coir material is sun-dried in polyhouses to reduce moisture levels below 20%. These polyhouses, built with concrete floors, ensure the material remains free from contamination by pests and pollens. This controlled drying process enhances the quality and cleanliness of the coir, making it ideal for various applications.

Rain water collection

Rainwater collected from our polyhouses and production sheds helps conserve this precious resource. It not only restores groundwater levels but also serves to wash the coir material, reducing the need for external water sources. This sustainable practice supports our commitment to environmental conservation and efficient resource management.

Customized production

The coir material is blended and compressed into various sizes to meet client specifications. Each batch undergoes rigorous quality checks during production to ensure consistency and high standards. This meticulous process guarantees that the final product aligns with customer needs, offering reliability and excellence in every order.

Packing

Coir products are packed in customized plastic bags, then palletized for container loading. Our in-house, specialized packing team ensures secure sealing of growbags and maintains pallet rigidity. This careful attention to packing quality ensures the products' safety during transportation, preserving their integrity until they reach the customer.